Download your copy of Zebra’s 2017 Manufacturing Vision Study today to learn how you can gain a competitive edge

In an eye-opening new vision study, 1,100 manufacturing executives were surveyed to analyse the state of the manufacturing industry worldwide, and to identify the key growth areas for technology prepare your business for the future.

Explore Zebra’s 2017 Manufacturing Vision Study

Quality Assurance

Industrial Internet of Things

Locationing

Operational Visibility

Is quality assurance high on your list of priorities?

Respondents to Zebra’s 2017 Manufacturing Vision Study say that quality management is their top priority, and it's clear that consistently ensuring high quality will play a key role in the smart factory of the future. In a world where finding a product defect after assembly can lead to sky-rocketing costs (not to mention brand-damaging customer dissatisfaction), putting processes in place that lead to better quality control are top of mind for many manufacturing executives.

Are you up to speed with the way data is now captured and shared?

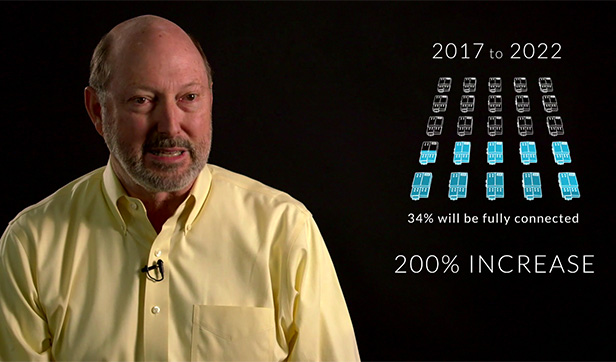

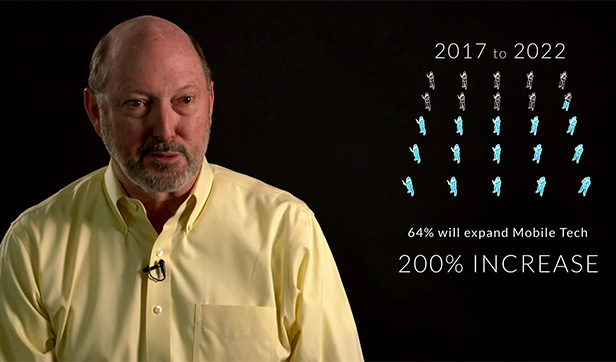

Zebra’s 2017 Manufacturing Vision Study reveals that while over 90% of manufacturers currently use IIoT technologies, most of the data is not connected to existing systems or centrally analysed. However, manufacturers recognise the benefits of a fully connected factory and supply chain visibility and plan to accelerate their investments.

End-to-end visibility of your assets, goods and personnel in real time.

According to the Zebra 2017 Manufacturing Vision Study, manufacturers plan to expand their use of real-time locationing technologies by 160% in the next five years.

Operational visibility starts right on the production line

The Industrial Internet of Things (IIoT) means manufacturers are capturing data at every point in the manufacturing process using sensors, tags and mobile technologies, increasing real-time visibility throughout their entire operation. This expanded visibility is essential for companies to remain competitive.